Propeller installation torque values

All propeller manufacturers are publishing different torque values. While all these values are generally within a ball park, there is a noticeable difference between wooden and metal propellers.

The following values for AN6 3/8 bolts.

Sensenich (metal - fixed pitch)

280 to 300 lb-in; 23 to 25 lb-ft; 31.6 to 33.9 newton-meters

Sensenich (wood - fixed pitch)

175 - 225 lb-in; 15 to 19 lb-ft; 20 to 25 newton-meters

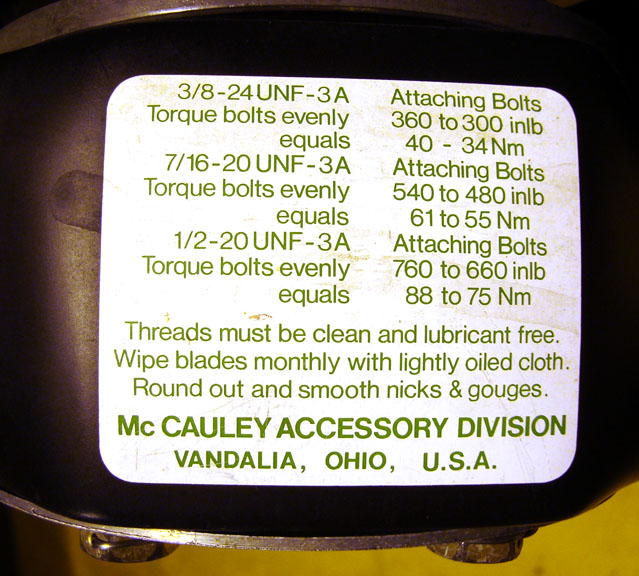

McCauley (metal - fixed pitch)

Torque (DRY): 360 to 300 Pound-Inches; 30 to 25 pound-Feet;

Chamfer in a metal prop:

Here is a summary of the conversations I had with McCauley. The specification for the chamfer around the mounting bolt holes is 0.031x45 on the 1A90. The critical measurement is the bearing surface under the bolt head/washer. The larger the chamfer, the less bearing surface. The maximum diameter of the chamfer on the hole should not exceed the diameter of the hole plus the chamfers on either side: .394+.031+.031 = .456.

Ron Raty

The McCauley installation instructions are calling for an AN960-616 flat washer under the prop bolts. Practice showed that these washers are too soft to withstand the forces acting here, as a result the washer compresses, loses tension and is wearing out the prop hole. Here a comment from John Schwaner: For use on bolts up to 160-180 ksi tensile strength per MIL-STD-1515A, table 209I. Caution is advised however, that real-world experience suggests that this washer is too soft for 160-180 ksi usage, especially at elevated temperatures. Thus use is limited to standard AN bolts or commercial Grade 5 bolts. For stronger bolts in tension the MS20002 washer is available.

A size comparison of the common AN960 washer with the harder MS20002 reveals that the MS20002 washer has a smaller diameter inner hole and a slightly larger outside diameter. The non-chamfered version offers approximately 20% more surface area to the nut. For example, a 1/4 inch AN960 has a surface area of .13989 sq. in. compared to .16998 sq. in. for the MS20002 thereby reducing the stress per square inch on the washer by spreading the load over a larger surface area. This helps prevent washer or faying surface crushing and reduces joint embedment relaxation.

It is highly recommended to use the MS20002 washer. It transfers the forces way better and saves the surface of your propeller.

McCAULEY INDUSTRIAL CORPORATION

SERVICE BULLETIN No. 13

To: Airframe Manufacturers, Direct Factory Distributors, Registered Distributors, Dealers, Civil Aeronautics Administration.

Subject: Removal of Operating Restriction Placards for Model 1A90 Met-L-Props Installed on Continental A-65, A-75, A-80, C-75, C-85 Engines.

These Placards were originally prescribed by the McCauley Industrial Corporation as a safety measure when the Met-L-Propeller was first introduced in 1946. The 100% safety record established by over 18,000 Met-L-Props which have been placed in service since that time has led us to recommend that the placards now be removed from subject installations.

The Civil Aeronautics Administration has approved the removal of these placards as evidenced by their confirming letter to us dated August 10, 1949.

All CAA Regional Offices have been advised regarding the removal of these operating restriction placards, and of the necessity for revising all aircraft specifications in which the McCauley Met-L-Prop Model 1A90 propeller installation is listed for Continental A-65, A-75, A-80, C-75, C-85 Engines.

The subject placards found included in Met-L-Prop packages in Dealer's and Distributor's stocks should be discarded and not placed on the instrument panel of the airplane at the time of the Met-L-Prop installation. Also the subject placards now attached to the instrument panels of aircraft should be removed and therefrom and discarded.

McCauley Industrial Corporation

Sensenich Metal Bolt Kit – 76AK Complete bolt kit for mounting 76AK Aluminum Propellers with no spacer attached. Includes (6) AN6H-32AS bolts with special thread length and (6) washers.

Wooden Props

The AN6H-41A is the correct length for a standard wood propeller hub. These are the same length as the original bolts that are specified in the parts manuals for the A and C series (and O-200) Continentals. The original Continental bolt is part number 24768 and differs from the AN bolt in having a minimum of 7/8" of thread vs. 9/16" on the AN bolt (to avoid bottoming the threads in the flange bushings, resulting in false torque), and apparently being of different steel composition than the AN bolts (3140 vs. 8740). Unfortunately the 23768 bolts are difficult to find. Sensenich recommends the AN6H-41A.