Fuel Systems

Beginning with s/n 2623, all production fuel tanks were fabricated from aluminum sheet. The fuselage/header tank capacity increased from five gallons to six gallons (nominal). From this time,

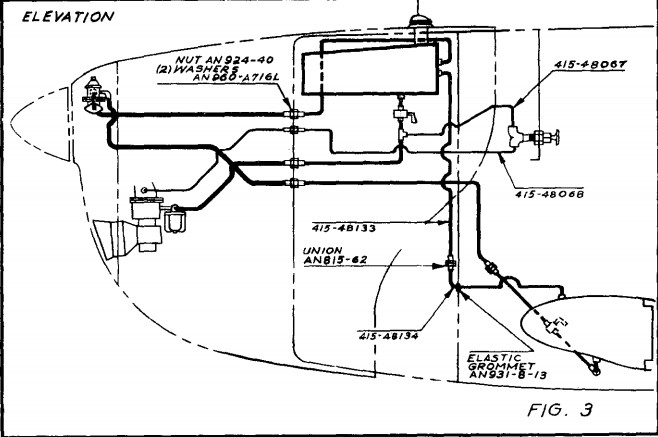

ERCO had four “production” aluminum tank fuel systems. Ercoupe Service Memorandum No. 43 issued on or about 10/15/46 includes three of these. The first, installed in Ercoupes 2623-3220, used fuselage/header tank 415-48120. The fuselage/header tank filling and overflow lines connected to fittings on the bottom of the tank. The far end of the overflow line now connected to a tee fitting in the balancing line between the wing tanks close to the left wing tank. The fuselage/header tank finger strainer projected up into the tank from a fitting in the bottom of this tank to which the line to the shut-off valve connected.

The second “intermediate system” installed in Ercoupes 3221-3467, used fuselage/header tank 415-48135. The fuel lines for filling and overflow connected to fittings on the rear bulkhead of the fuselage/header tank. The far end of the overflow line now connected to a fitting in the top of the left wing tank. From s/n 2623-3467 the fuselage/header tank finger strainer was located in the bottom of these tanks.

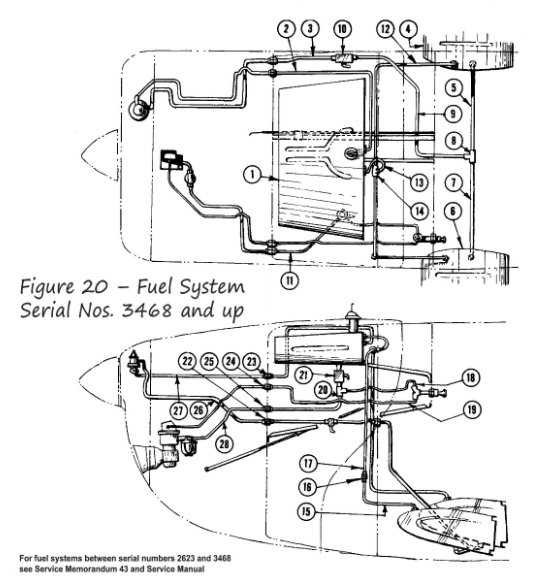

Their third “improved system” installed in Ercoupes 3468-4423 used fuselage/header tank 415-48145. The overflow line, still connecting to a fitting in the top of the left wing tank, was increased in size. The fuselage/header tank finger strainer was now located with the fuel shut-off valve.

All Ercoupes to s/n 4423 require vented wing tank caps because one or both wing tanks cannot vent back to the fuselage/header tank.

Fourth Commencing with s/n 4424, the Model 415D (and up) fuel system depicted in the Ercoupe Parts Catalog on p.28, Fig. 20 became standard. Much of the information referring to Ercoupes 3468-4423 on this drawing is misleading or wrong. Fuselage/header tank 415-48145 now had its overflow line split with a “tee” fitting (415-31240-22) and a separate overflow/vent line connects each wing tank. These Ercoupes require unvented wing tank caps because both wing tanks now vent back to the air space in the fuselage/header tank.

The 415-CD model, commencing with s/n 4501, was just a 415-D with 13º “up” elevator (instead of 9º), a gross weight of 1260 lbs. (instead of 1400) and different placards. Approximately 114 415-C airframes still in dealer hands (unsold) were factory modified in the field to full 415-CD specification. These airframes require unvented wing tank caps for proper function, AS DO ANY ERCOUPES WITH SEPARATE OVERFLOW/VENT LINES BETWEEN THE FUSELAGE/HEADER TANK AND EACH WING TANK.

Per the preceding, one can see that things were quite orderly up until on or about 12/30/46 when ESM 39 was issued. This explained how to replace the original terneplate wing tanks in s/ns 813-2622 with “production” aluminum tanks 415-48187 L&R. Any Ercoupe between s/n 813 and 2622 with one or more aluminum wing tanks would have been modified per ESM 39. Whether terneplate, stainless and aluminum, these were all tanks of 9 gallon (nominal) capacity.

THEN, on or after 6/1/47, ESM-50 was issued. This announced the availability of “retrofit" aluminum tanks for serials 813-2622 of smaller size (8 gallon nominal capacity). These are the tanks listed in Aircraft Specification No. A-718, item 108. They actually hold only 7.7 gallons, and NO Ercoupes left the ERCO production line with these tanks. They have no specific provision or specification for a fuel gauge (required by Aircraft Specification A-718 production drawings). A “special” in-fuel-cap float gauge was available, and today a “Rain-pruf” special order gauge is available from Skyport

So it can be seen from the preceding that it is only Ercoupes from s/n 813 and 2622 with aluminum (instead of stainless) wing tanks require detailed examination as to which tanks and fuel lines are fitted. That's 1809 of the total 4423 415-C models. Plus the 114 modified to 4150CD specification, total 1923 of 4423, or 44% of “the fleet”.

WRB