Corrosion in the elevator control horn area - wide elevator

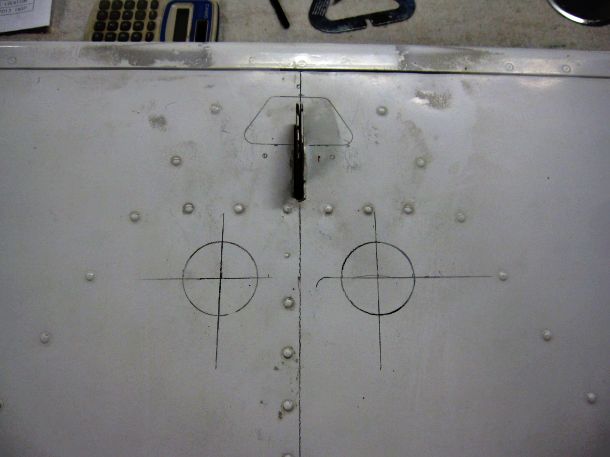

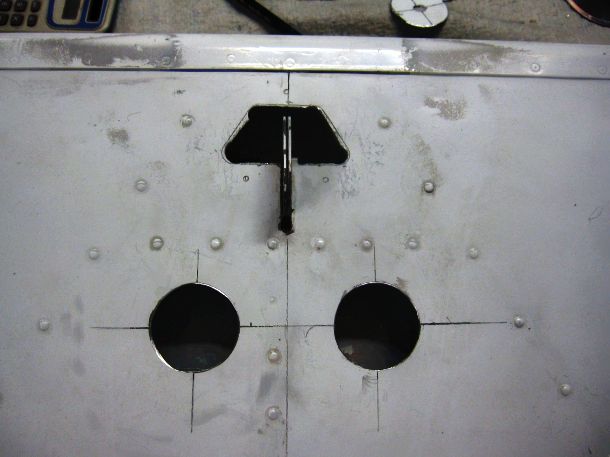

Service Bulletin 34 recommends adding inspection holes to the elevator.

The following images speak for themselves to the reason why.

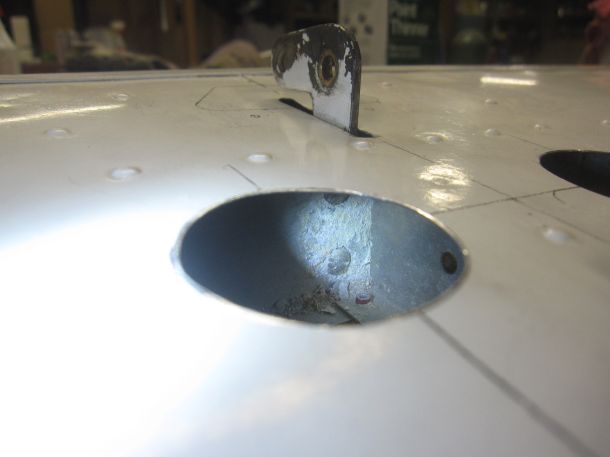

SB34 speaks of dissimilar metal corrosion. The pictures show how stainless steel screws meet aluminum and steel.

Aluminum sacrifices for steel and both sacrifice even more against stainless steel.

Such a mix should be avoided and at least carefully corrosion protected.

A nice picture of the corrosion nest that builds up around the stainless steel screw head. Aluminum is the anode and stainless is the cathode. In the presence of an electrolyte, the stainless steel is protected and the aluminum is corroded. Vibration and rubbing between the screw head and the aluminum destroys the naturally occurring oxide film that normally protects aluminum. The protective oxide film on aluminum is normally self-renewing, however, under a screw head the absence of oxygen prevents it from renewing.

Stainless parts used on aluminum should be cadmium plated and primed to prevent galvanic corrosion. This is a Boeing Aircraft practice per Boeing-Aero-#07 publication "Design for Corrosion Control"

To further quote Boeing: "Stainless steel parts are cadmium plated and primed if they are attached to aluminum or alloy steel parts. This is to prevent the stainless steel from galvanically corroding the aluminum or alloy steel. For the same reason, titanium parts are primed if they are attached to aluminum or alloy steel parts. "

John Schwaner

The control horn itself is made from steel and the surrounding aluminum sacrifices in conditions that promote corrosion (humid environments).

Hartmut

| << previous | next >> |